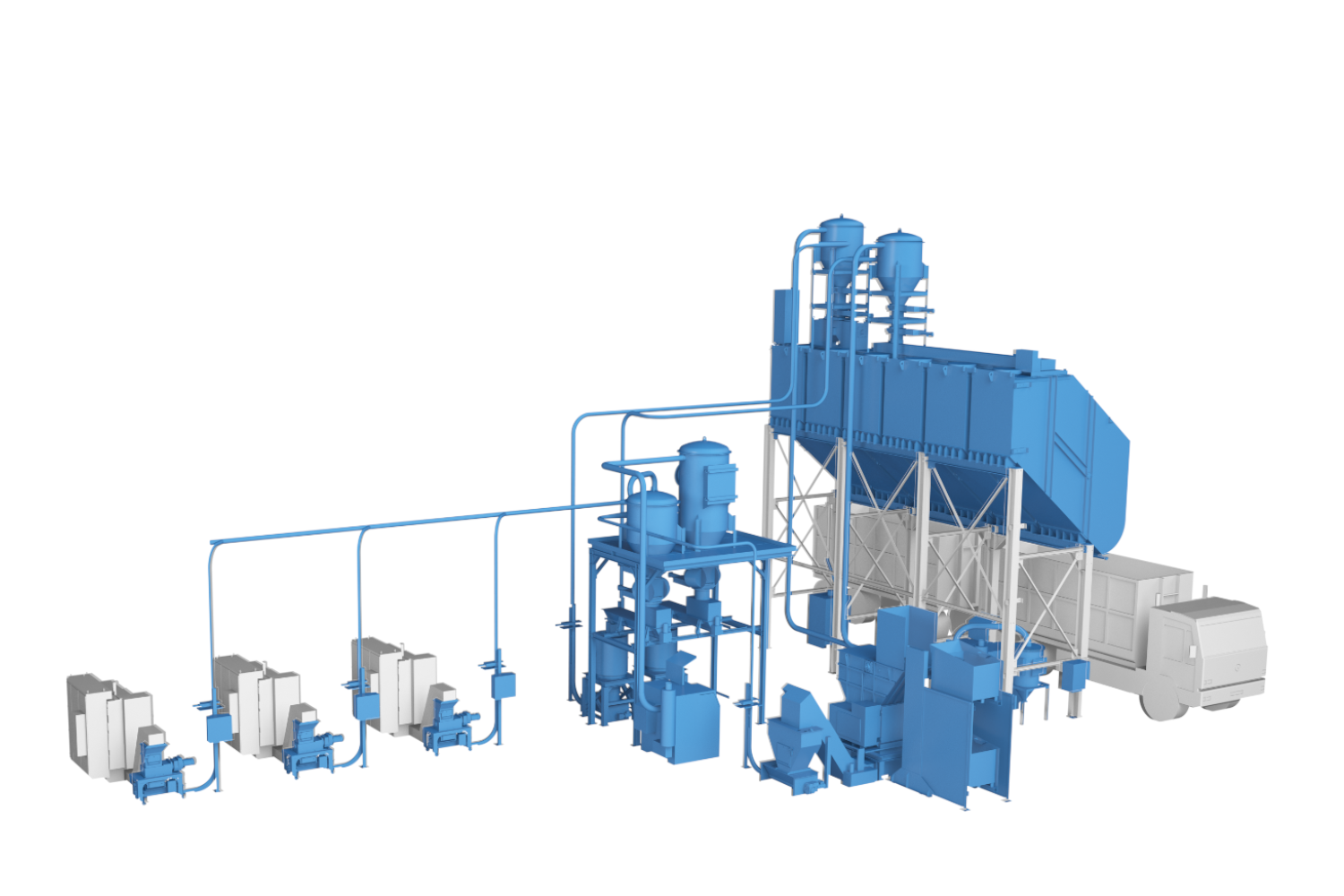

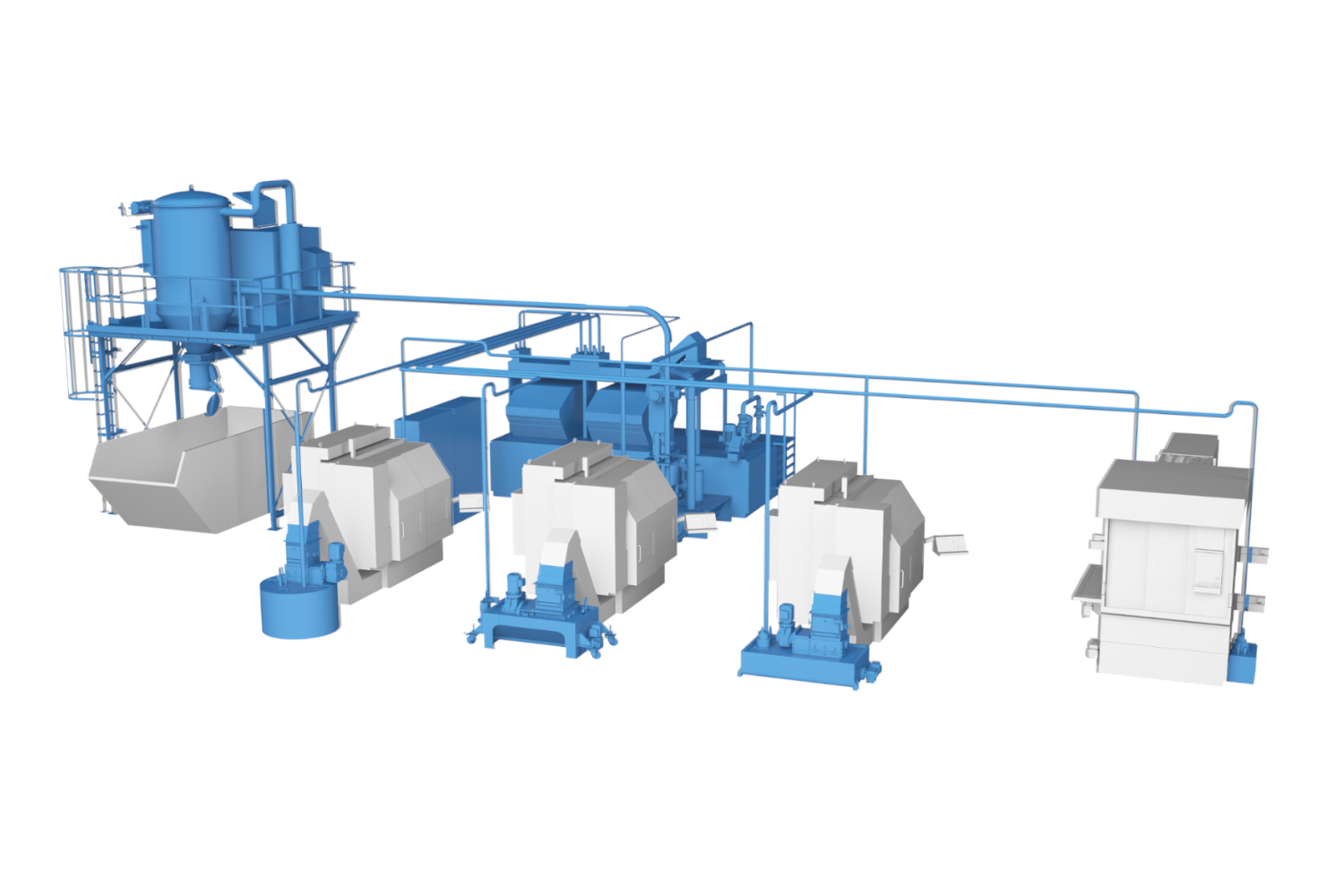

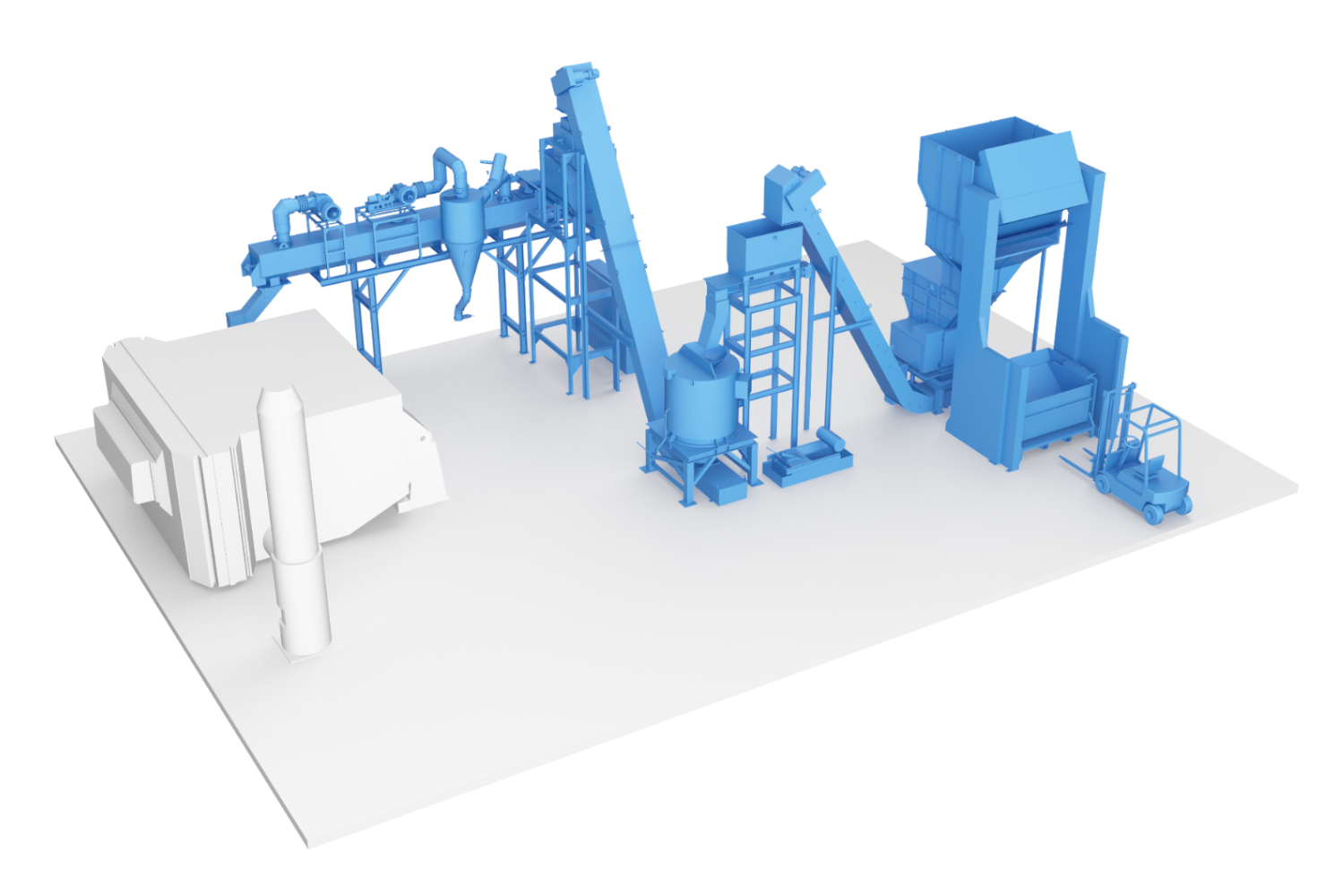

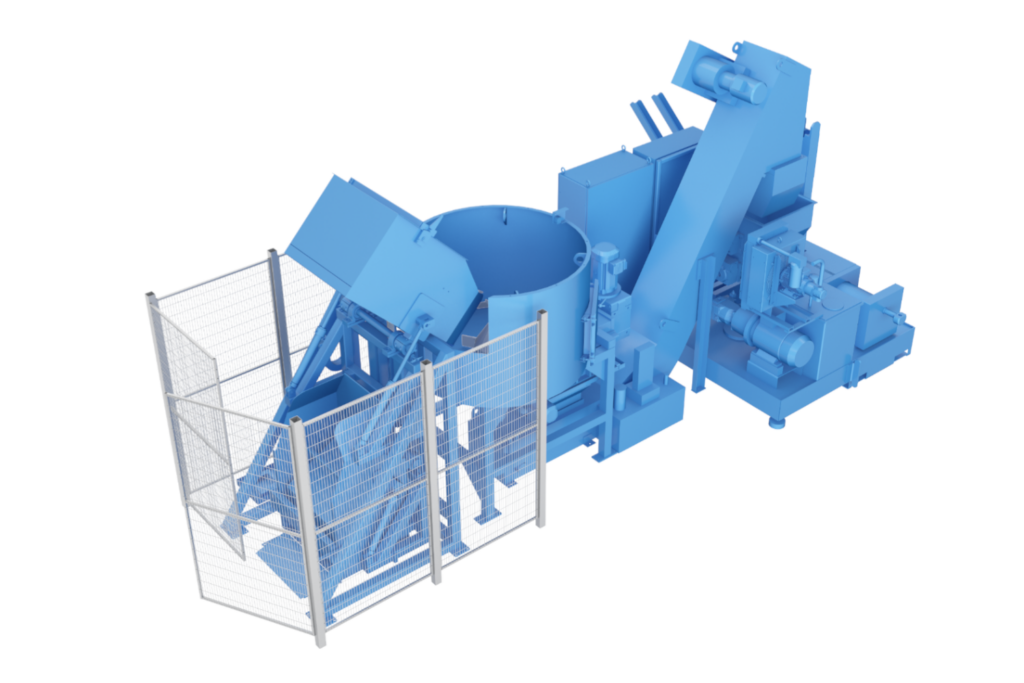

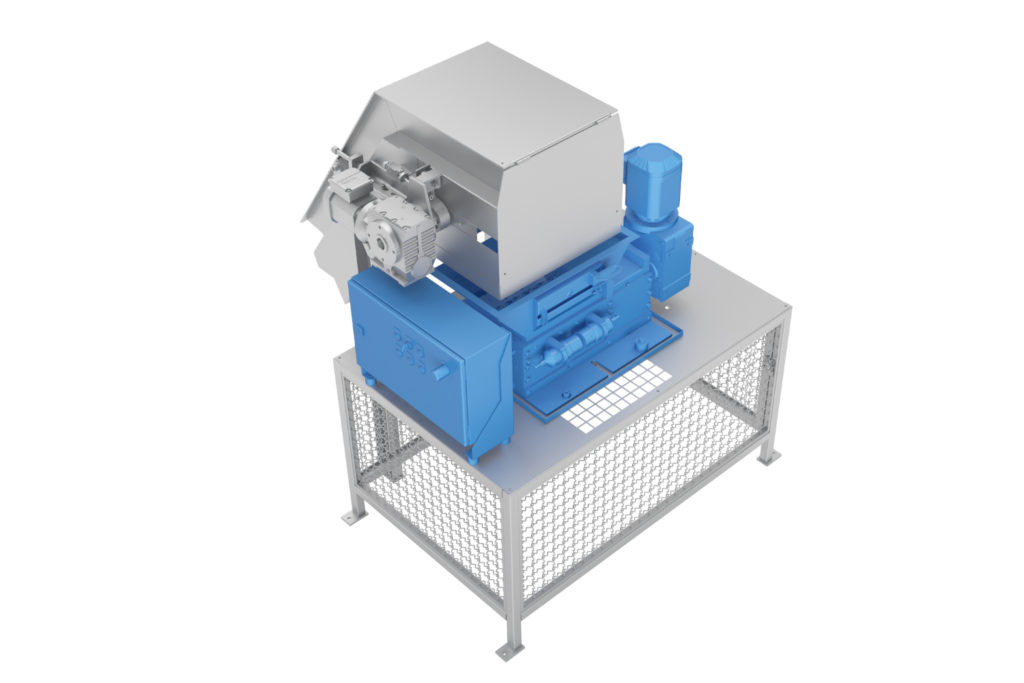

Especially in aluminium processing companies, accumulated chips, sprues and other “scrap” are not sold but directly crushed and recycled. The shredded chips are dried, brought to temperature and fed into the melting furnace in suitable quantities together with the new raw material. This can be handled in large lines – see above – but also in smaller manual plants as shown here. In all cases, precise monitoring of the chips with regard to size, temperature and quantity is important. This is the only way to achieve an optimal melting process.

Aluminium processing companies pay very close attention to energy and resource efficiency, and ARP is an ideal partner here.